Installed Base Evaluation

|

The right parts, in the right place, at the right time: Installed Base Evaluation™ from Agilix Solutions and Rockwell Automation

When it comes to production, nobody likes surprises. Yet it can be difficult to predict when and how equipment will fail us, either because of problems or because it has reached the end of its useful life. Choosing not to plan for equipment failure may give you one less thing to worry about today, but it gives you a much larger problem to worry about tomorrow when a production line comes to a screeching halt.

When was the last time you conducted a thorough analysis of your critical plant assets and their condition?

- Do you have an accurate plant model identifying all of the Physical Assets in your plant?

- Do you know your obsolescence risk?

- Do you have the right spare parts if a line goes down?

- Do you know what Rockwell software you're running, and if you have a support contract for each package?

If you answered "No" to any of these questions, you may need an Installed Base Evaluation (IBE).

Agilix Solutions and Rockwell Automation help you better understand and pinpoint your lifecycle risk by site, area, line, machine and panel. By optimizing your maintenance, repair and operations (MRO), we’ll help ensure you have the right parts, in the right place, at the right time.

We provide a site-delivered service that offers actionable intelligence to help you make data-driven decisions regarding the support and obsolescence management of your installed base assets.

Multiple options available:

Level 1 – Rockwell Automation Repairable Products Only

Includes analysis and documentation of PLC (and associated power supply/chassis), I/O, VFD and HMI.

Level 2 – Rockwell Automation and Third-party Repairable Products Only

Includes analysis and documentation of PLC (and associated power supply/chassis), I/O, VFD and HMI.

Make data-driven decisions regarding the support and obsolescence management of your installed base assets. We can help you:

- Reduce costs by identifying and eliminating excess inventory, which can help improve return on net assets (RONA).

- Increase uptime by ensuring critical spares are on-site to support production and maintenance.

- Identify and mitigate risks associated with supporting legacy equipment.

- Gain broader visibility into your plant assets.

Check out this brief informational video outlining core benefits of an Installed Base Evaluation.

Informational Blog Articles:

|

Every IBE follows a detailed four-step process: Step 1 – Field Collection

Step 1 – Field Collection

On-site data is collected by the Agilix Solutions team. During a site visit, we work with you to develop a systematic model for data collection, which can include a review of your complete electrical and mechanical installed base. We focus on the process and machines in place, providing analysis in the context of your most critical facility performance.

Step 2 – Processing

Using customized software for analysis, we determine plant lifecycle risks and overall maintenance, repair and operations (MRO) inventory status. To determine recommended inventory levels, we review your products installed, plant operating hours and product mean time between failure (MTBF) data.

Step 3 – Delivery

Using a consultative approach, Agilix Solutions delivers analysis and recommendations to you, developing an action plan that best suits your business. Provided reports detail what’s installed, what’s missing and what equipment is nearing end of life. Our team of experienced professionals will discuss the most effective solutions to improve plant performance.

Step 4 – Ongoing Insight

You’ll gain access to a subscription term of My Equipment, which will help you assess and evaluate your risks on an ongoing basis.

|

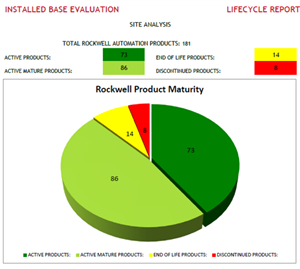

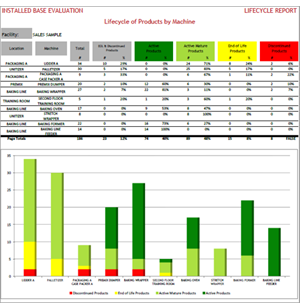

What your final analysis includes:

- Easy-to-read reports that indicate the lifecycle status of all parts

- Identification of critical spares, including excess, insufficient and inactive spares

- Lifecycle analysis

- Summary by plant

- Risk by line, machine

- Risk by catalog number

- Inventory analysis

- Summary of spares analysis

- Recommendation of stocking levels based on MTBF and plant operating hours

- Detailed report including active, excess and inactive spares

- Plant analysis

- Detailed reports by plant, area, department, line, machine, panel and catalog number

- Environmental condition reporting

Enterprise, software and custom reporting are also available upon request.

|

Helpful Reference Material

An Installed Base Evaluation can help you optimize today and plan for tomorrow. Contact Agilix Solutions to get the conversation started.

Kelly McLure

Sales Specialist

kmclure@goagilix.com

Office: 901.334.4832

Mobile: 901.530.6534